Custom Wire Harness Assembly

Many electronic systems rely on robust wire harnesses or looms to provide reliable interconnections for optimal performance. At Production Logix, we understand how critical these wire harnesses are—whether you are in automotive, telematics, industrial equipment, consumer electronics, or any field where electrical connections must endure vibration, environmental stress, or long operational life. Our mission is to deliver wire harness assembly services that perform correctly the first time, every time.

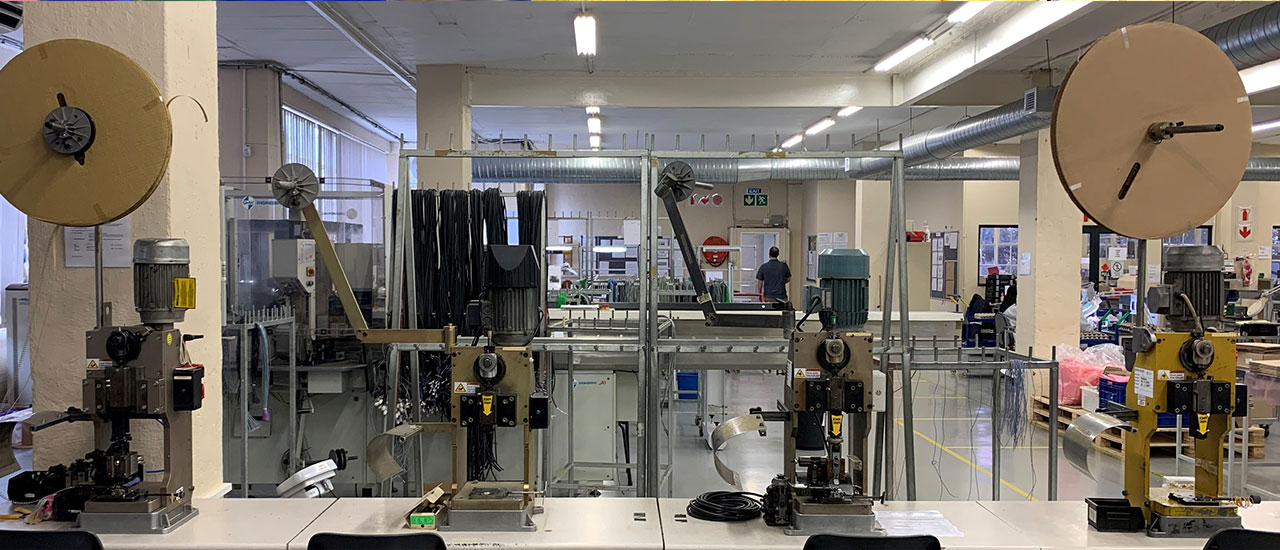

With over 20 years’ experience in cable and harness manufacturing, we are pioneers in the industry. We know what standards, materials, and processes are necessary to ensure high quality, long-term reliability. Our team uses state-of-the-art machinery and proven manual techniques—combined with rigorous testing—to give you harnesses built for purpose.

What We Offer

Our wire harness assembly services include:

-

Cut & Strip – precision cutting of wires to length, accurate stripping to ensure good terminations.

-

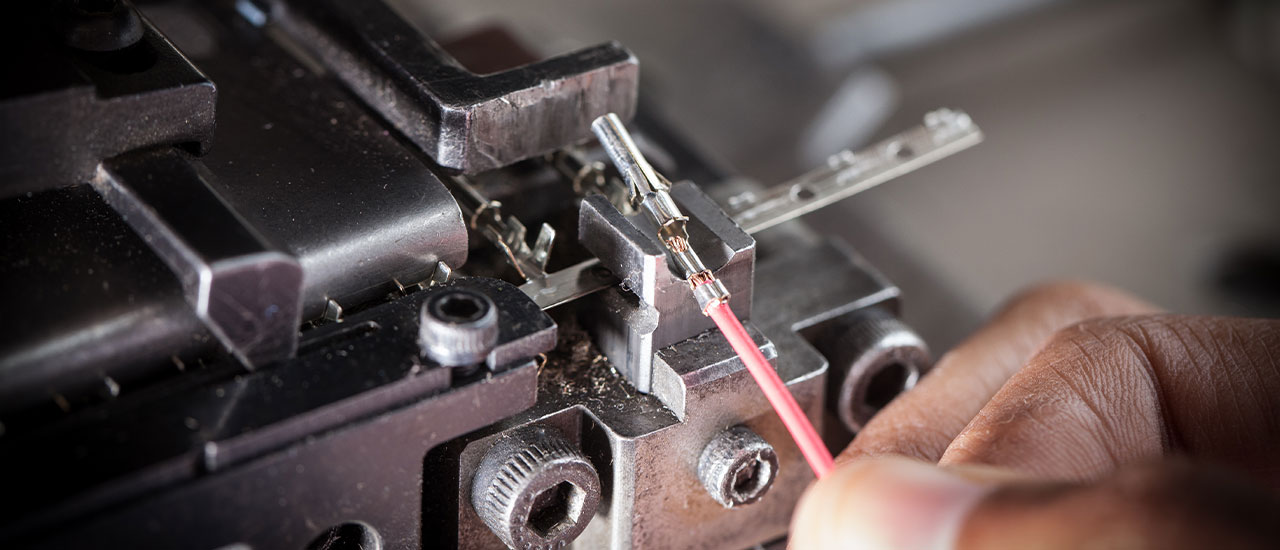

Crimping & Soldering – secure contacts, whether crimped or soldered, to ensure low resistance and strong mechanical bonding.

-

Sleeving, Heat Shrinking & Taping – for insulation, protection from abrasion, moisture, and neatness.

-

Splicing & Jointing – when combining conductors or branching wiring paths.

-

Labeling & Identification – every harness is clearly labeled for ease of installation, servicing, and traceability.

-

Flexible & Semi-Rigid Coaxial Assembly – for specialized signal or RF applications.

-

Testing & Quality Assurance – electrical continuity, insulation resistance, custom functional testing; every harness is inspected thoroughly.

-

Procurement of Components – we source wire, connectors, terminals, sleeves, and other raw materials to ensure compatibility and durability.

Why Choose Our Wire Harness Assembly?

-

Durability & Mechanical Integrity: Assemblies engineered to handle vibration, bending, vibration fatigue and harsh environments.

-

Custom Design & Flexibility: Tailored harnesses to fit your layouts, connectors, lengths, routing, and environmental constraints.

-

Cost-Effective Solutions: By managing procurement, optimizing harness bundles, and minimizing waste, we help reduce total cost.

-

Compliance & Industry Standards: We meet relevant industry norms (automotive/telematics standards, insulation ratings, IP ratings where applicable) to ensure safety and performance.

Industries We Serve

We produce harness assemblies for a wide range of sectors, including:

-

Automotive & Telematics

-

Industrial Machinery & Controls

-

Consumer Electronics

-

Renewable Energy & Solar Systems

-

Telecommunications & Networking

- Cut & Strip

- Crimping

- Sleeving

- Heat shrinking

- Taping

- Splicing

- Soldering

- Testing

- Labelling

- Procurement

- Flexible and Semi Rigid Coaxial Assembly

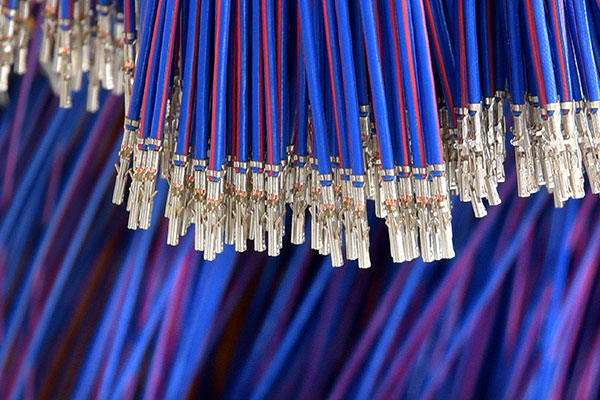

- Wire Harnesses

- Cable Assembly

- Loom Assembly