Through-hole technology

Enhancing performance and reliability with Through-hole technology

At Production Logix, we believe that strong foundations make for dependable products. Our through-hole technology services are built upon decades of PCB assembly experience, and are designed to deliver both performance and durability – especially in environments where reliability is non-negotiable. Whether you’re building industrial equipment, medical devices, or rugged electronics, through-hole assembly remains a go-to method for its mechanical robustness and ease of repair.

What We Offer

To ensure that your assemblies meet or exceed expectations, our comprehensive through-hole service includes:

-

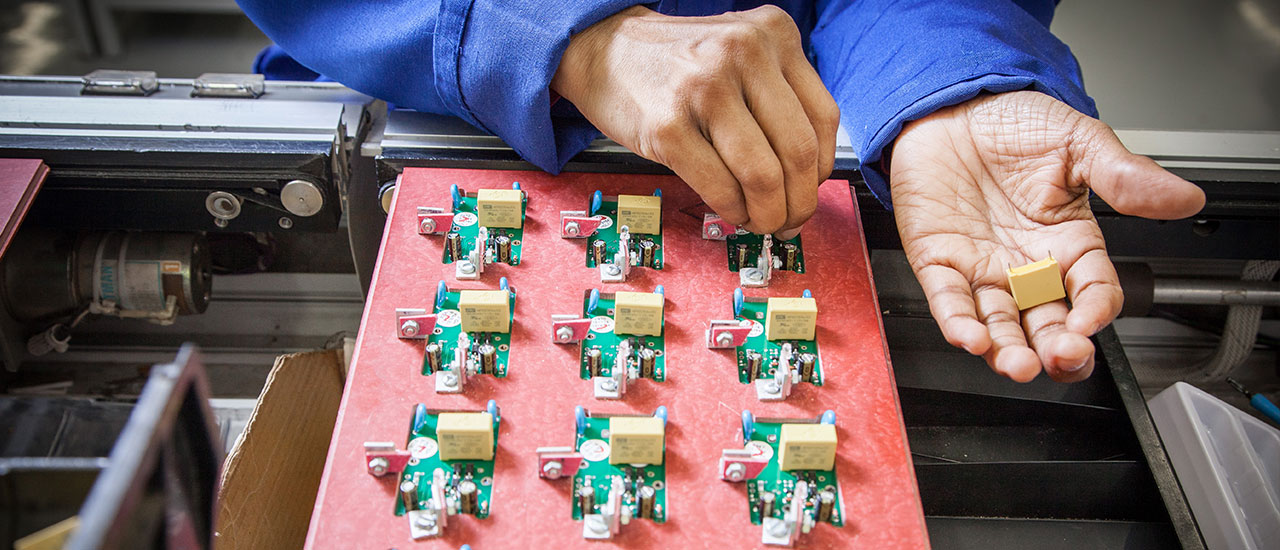

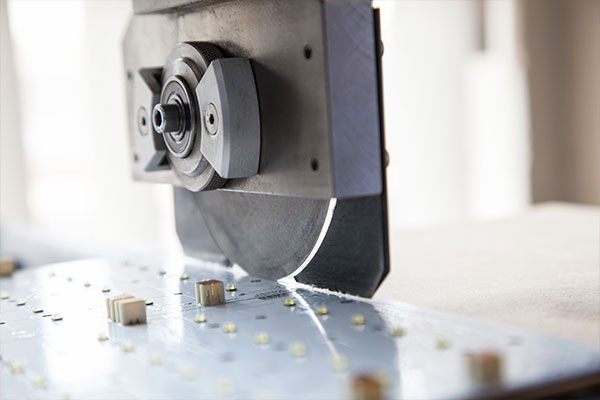

Component Cropping & Forming: We adjust components to the precise lengths and shapes required, reducing stress and optimizing fit.

-

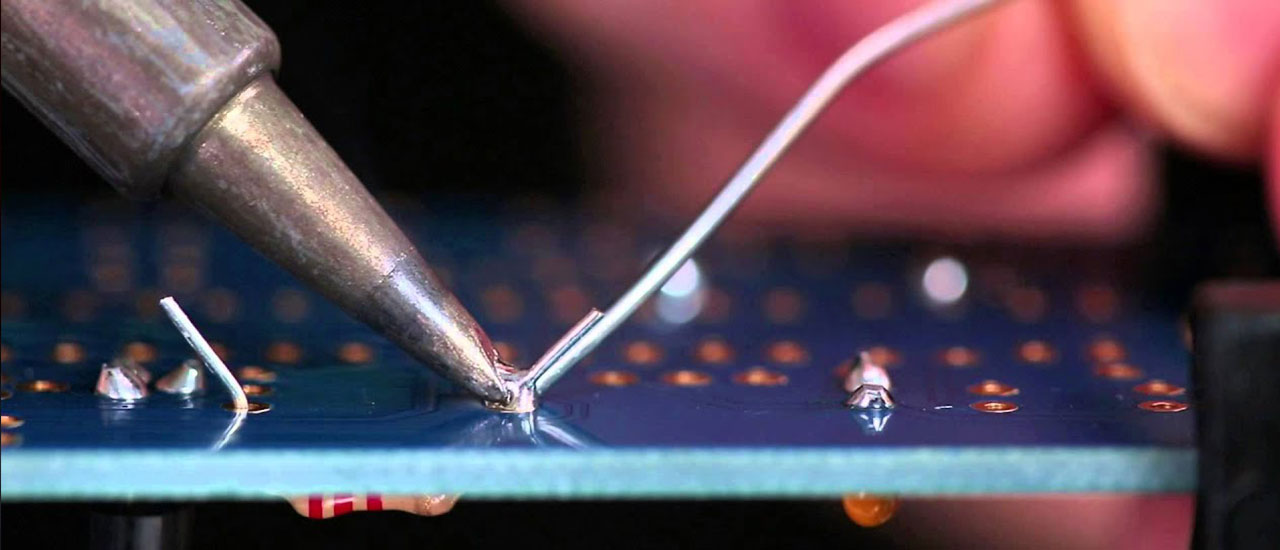

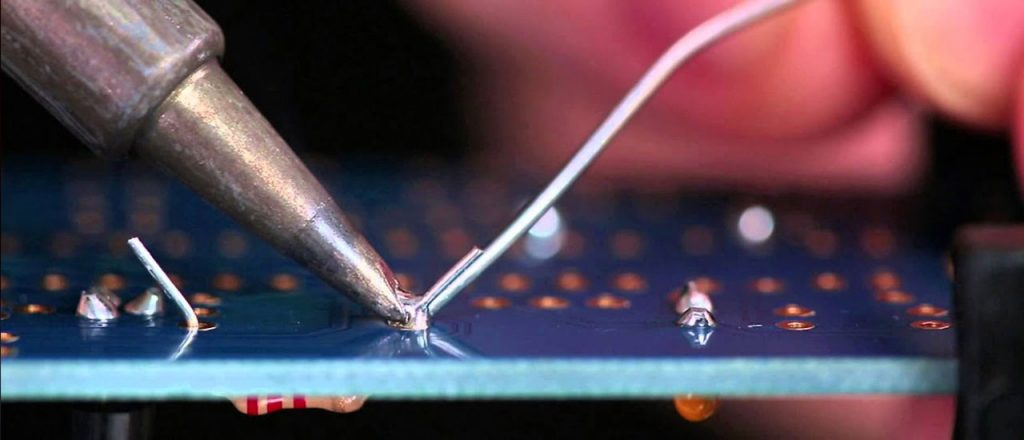

Hand Soldering: For fine work or components not amenable to automated processes, our skilled technicians solder by hand with precision and care.

-

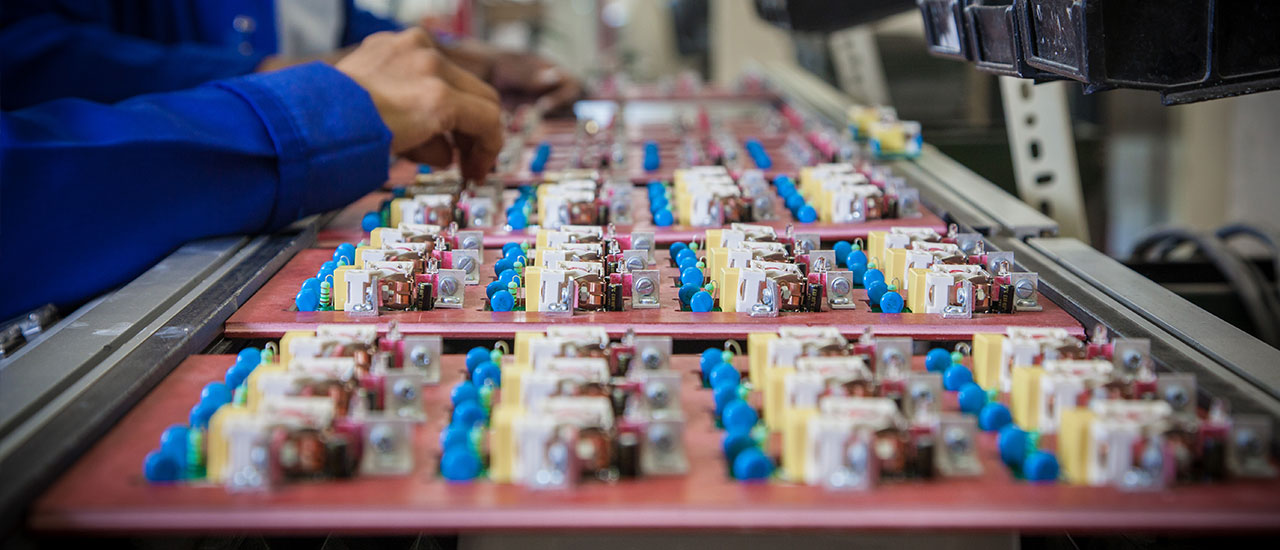

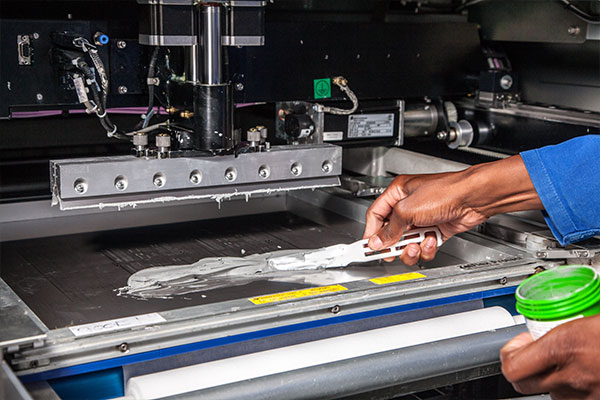

Wave Soldering: For high-volume boards, we use industry-standard wave soldering to ensure reliable solder joints with consistent quality.

-

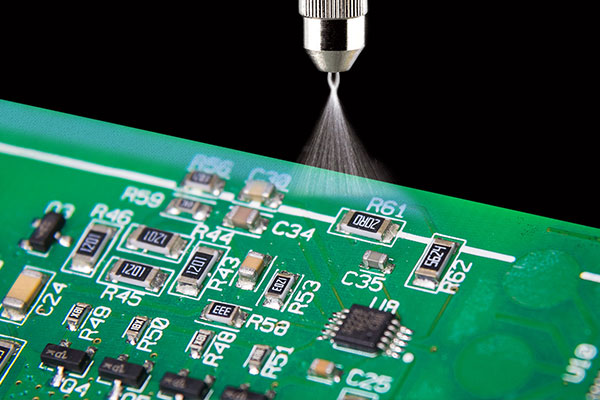

Gluing, Conformal Coating & Encapsulation: To protect assemblies from moisture, dust, vibration, and other environmental stresses, we offer protective coatings and encapsulation.

-

Programming & Testing: Beyond just building, we verify and program your boards so that they are ready to go out of production or into deployment.

We operate multiple assembly lines, allowing us to scale up when needed, while maintaining short lead times so you don’t have to compromise on speed. Whether you prefer Tin-Lead or Lead-Free soldering processes, we cater to both, depending on your project’s specifications or regulatory requirements.

Quality & Standards

Quality is at the heart of everything we do. All through-hole assemblies are capable of being produced to IPC Class III standards, which means they’re suitable for high-reliability applications where continual performance is critical. Every solder joint is evaluated, and rigorous testing ensures that the boards can withstand stress, thermal cycling, and long-term use.

Why Choose Through-Hole?

Though surface-mount technology (SMT) is suitable for many applications, through-hole assembly still excels in certain scenarios:

-

Mechanical Strength: Through-hole components are more securely anchored, which is crucial for connectors, switches, or parts exposed to physical stress.

-

Repairability & Modifications: Easier to desolder and replace components, which is useful in low-volume or maintenance-heavy applications.

-

Through-Hole-Only Components: Some components simply don’t exist in SMT form or are prohibitively expensive, making through-hole necessary.

Are you looking for a consumer ready product? No worries, we can handle that too. Please look at our Box Assembly Service for more information.

- Tin-Lead or Lead Free Process

- Low Lead Time

- IPC Class III

- Wave Soldering

- Hand Soldering

- Component Crop & Form

- Conformal Coating

- Multiple Assembly Lines

- Programming & Testing

- Electronics Manufacturing

- PCBA Assembly

- PCB Assembly

OTHER SERVICES INCLUDE:

- Conformal Coating

- De-Panelling

- De-tabbing

- Testing

- Prototyping

- DFM

- Procurement

- Final Assembly