KwaZulu-Natal based Production Logix is a prominent player in the electronics manufacturing sector in South Africa, with its products driving key elements of the aerospace and defence sectors as well as mining, security, and transportation.

As the company boldly states, in an era where precision, reliability, and rapid innovation are non-negotiable, electronics play a critical role in powering the backbone of modern defence and aerospace systems. From advanced avionics to mission-critical communications and control systems, the ability to deliver high-performance, custom-built electronics at scale is what enables today’s military and aerospace platforms to operate with confidence in the most demanding environments.

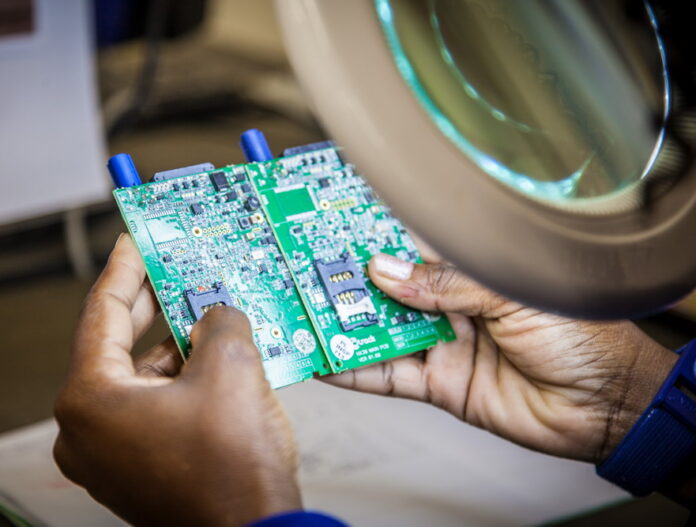

Production Logix specialises in PCB (printed circuit board) assembly, through-hole electronic circuit assembly, and ruggedised wire harnessing. Other services include prototyping, surface mount assembly (SMA), potting, and coaxial manufacturing.

Backed by more than 30 years’ experience in the electronics environment, Production Logix’s manufacturing facility, comprising five assembly lines, can turn out up to 300 000 components per hour. This is to satisfy the insatiable demand for its product solutions across a wide field.

Many leading South African aerospace and defence companies make use of Prologix, including radar, countermeasures, antennas, satellite and communications manufacturers. Prologix has seen considerable growth since the company was acquired by current management in 2016, going from a handful of key customers to over 30 core customers, with nearly half of business coming from the aerospace/defence sector. Although all Prologix customers are local, the company is able to export as required – it has Directorate Conventional Arms Control (DCAC) certification for defence contracts.

Although Prologix experienced a slump during the Covid-19 pandemic along with the rest of the industry, it has seen a major recovery, largely due to an increase in global military spending. Technology enhancement in the aerospace industry has also filtered down to benefit the company.

Production Logix does a lot of work for the defence industry, but is not reliant on defence business and also operates in the mining and automotive segments, including telematics (monitoring cars, trucks, equipment and other assets using GPS technology and on-board diagnostics). Vehicle tracking companies have been keeping Prologix busy with tracking system looms. Components for water metres, and cabling and looms for inverters, batteries, and cell phone towers are also regularly manufactured by the company

The Production Logix offering is based on contract manufacturing and the required flexibility involved in dealing with unique client specifications and data packs. “We do not own any intellectual property (IP), nor do we develop products. We only build the range of electronics and harnesses for clients on their behalf according to their own specifications. This is essential for confidentiality and IP security,” said Shilpa Mehta, Managing Director. “One of our strengths is we work very hands on with our customers.”

By offering a turnkey solution, Prologix manages every step of the production process, from component procurement and inventory control to warehousing and surface mount assembly, through hole assembly and final assembly. “Our sophisticated ERP platform underpins our warehouse management system, ensuring seamless inventory tracking, precise order fulfilment, and efficient resource management. This integrated approach allows us to streamline production and offer clients a single, reliable point of contact, which simplifies coordination and enhances efficiency,” Mehta said.

“Our commitment to quality, flexibility, and innovation allows us to adapt our services to the specific requirements of each customer, recognizing that no two clients are the same,” Mehta added. “Each customer’s needs are unique, and we pride ourselves on being adaptable.”

Focus on quality

Mehta noted that the defence industry requires high quality standards, and this ensure high quality is maintained across the whole business. “We have a reputation in the market for a very high standard of quality that helps us with our commercial customers, especially those who have been burnt with poor quality before. With us we try and get the product right the first time.”

The company’s absolute focus on quality is non-negotiable, Mehta emphasised. Production Logix has ISO 9001-2015 certification and is compliant with AS9100 Military and Space accreditation, the globally recognized Quality Management System for the aerospace industry. “This certification reflects our dedication to meeting the stringent requirements of aerospace and defence clients, while also ensuring reliability across other sectors,” Mehta said.

“AS9100 certification isn’t just a badge—it’s a reflection of our rigorous quality commitment. Whether our products are destined for a military aircraft or a commercial project, we maintain the highest standards of performance and safety.”

In addition to AS9100, Production Logix operates according to IPC Class 3 standards, which set the highest level of performance criteria for electronic assemblies. This level of compliance is critical for products used in challenging environments, where failure is not an option. “With IPC Class 3, we’re able to meet the highest industry standards and deliver dependable results, no matter the application,” Mehta added.

Production Logix is the only Level 1 BBBEE Contract Electronics Manufacturer in South Africa catering to the defence and aerospace industries, demonstrating its commitment to economic empowerment and growth within South Africa’s manufacturing landscape. “Our BEE Level 1 status is a fundamental part of who we are,” said Mehta. “We believe in creating meaningful, high-value opportunities for South Africans in advanced technology and manufacturing, especially as we work to build local industry and expertise.”

Production Logix employs around 120 permanent staff, but brings in many contract staff as needed, depending on projects. “Many of our staff have been with us for 15-20 years so there’s a lot of institutional knowledge in the company,” Mehta emphasised.

“Through our BEE Level 1 certification, AS9100 and IPC Class 3 compliance, and flexible approach, Production Logix remains a trusted Electronics Manufacturing Services provider for aerospace, defence, and beyond,” Mehta said. “Whether it’s a tailored solution for a high-stakes defence project or support for a different market sector, we are here to meet each client’s unique requirements. Our flexibility and dedication to quality make us a partner of choice for the most demanding industries,” she concluded.