PCB Assembly: Excellence Delivered by Production Logix

In today’s fast-paced electronics industry, pcb assembly is the cornerstone of transforming sophisticated designs into functioning products that drive innovation across sectors like aerospace, defence, industrial systems, and consumer electronics. At the heart of this critical process stands Production Logix, a leading Electronics Manufacturing Services (EMS) provider based in Pinetown, KwaZulu-Natal, offering comprehensive pcb assembly services tailored for precision, reliability, and scalability.

Comprehensive PCB Assembly Services

Production Logix’s approach to pcb assembly encompasses various advanced services:

-

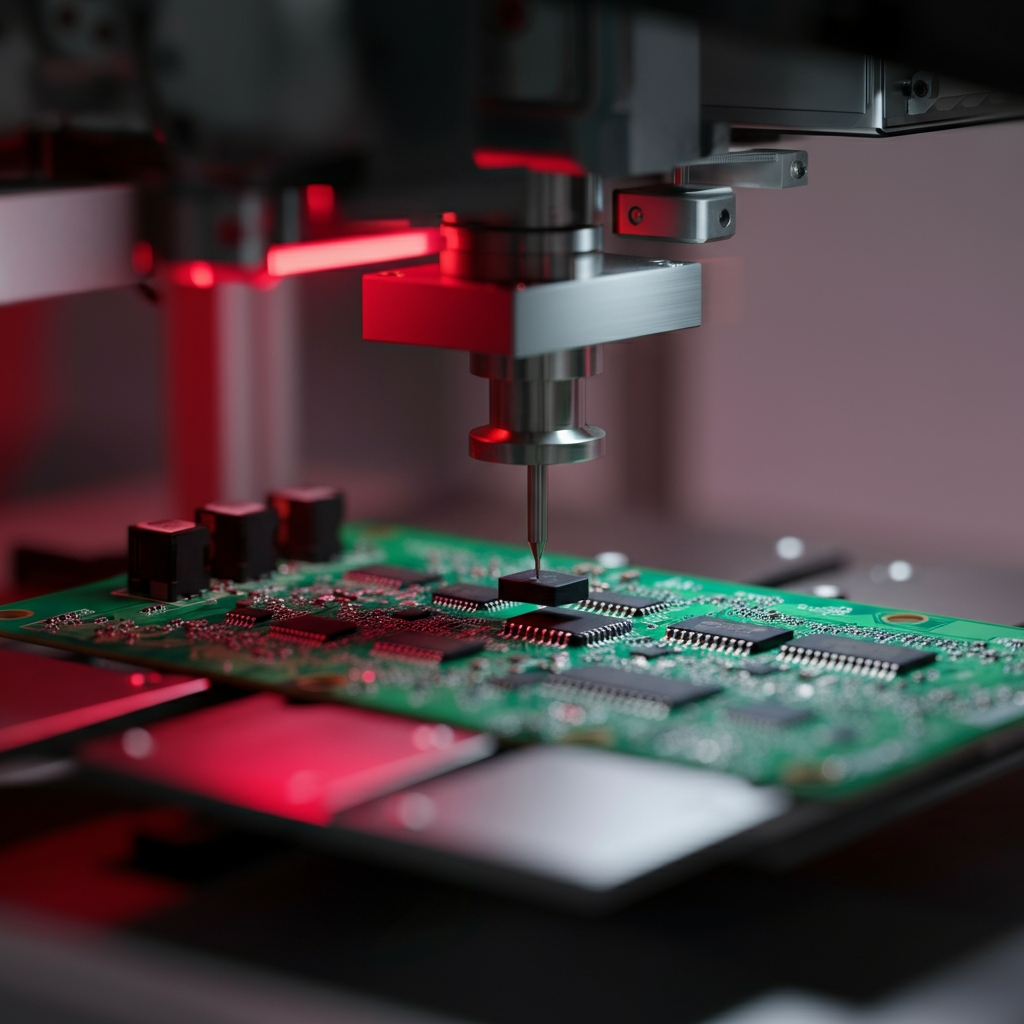

Surface-Mount Assembly (SMT): Utilizing five high-capacity SMT pick-and-place lines, Production Logix delivers unmatched flexibility—handling everything from ultra-fine pitch components (like 0201 devices) to high-volume batches with short lead times and no minimum order quantities (MOQs)

-

Through-Hole Assembly & Turnkey Solutions: Whether your design calls for through-hole components or a full box build, Production Logix provides turnkey PCB solutions—from prototyping to final system assembly.

-

End-to-End Capabilities: Supporting the full electronics manufacturing lifecycle, they offer services including prototyping, design-for-manufacture (DFM), conformal coating, PCB washing, de-paneling, testing, wire harnessing, and procurement.

Unwavering Commitment to Quality

Quality is never optional—it’s the foundation of every pcb assembly at Production Logix:

-

Industry-Leading Standards: The company meets the rigorous benchmarks of IPC Class 3, AS9100 (Military and Space quality management), and ISO 9001:2015. This dedication to excellence applies not only to defence and aerospace projects but also to commercial and industrial clients.

-

Zero-Defect Culture: Their philosophy centers on preventing defects rather than fixing them. This proactive approach helps clients avoid costly recalls, reputational damage, and production delays.

-

Advanced Inspection Techniques: Inline 3D Automated Optical Inspection (AOI) and Solder Paste Inspection (SPI) systems allow Production Logix to spot issues like lifted pins or paste misalignment early—when corrections are most feasible and cost-effective.

Industry-Specific Expertise

Production Logix isn’t just a pcb assembly services provider—they’re a trusted partner for high-stakes industries:

-

Aerospace & Defence: Supporting clients in avionics, radar, satellite communications, and more, Production Logix supplies electronics that perform reliably in the most demanding environments. Their AS9100 and IPC Class 3 compliance ensures mission-critical standards are met.

-

Commercial & Industrial Sectors: Beyond defence, they tackle projects in automotive, mining, telematics, metering, and consumer electronics—such as producing tracking system harnesses, inverter cables, and meter components.

-

Strategic Turnkey Partner: With full inventory management, ERP-backed warehouse control, and end-to-end production—which includes procurement, surface-mount and through-hole assembly, and final assembly—clients benefit from seamless coordination and a single point of contact.

A South African Engine of Innovation & Empowerment

Rooted in South Africa and proudly positioned as the only Level 1 B-BBEE contract electronics manufacturer serving defence and aerospace, Production Logix embodies both quality and empowerment. With around 120 permanent staff and a pool of seasoned professionals—many serving over a decade—they combine institutional knowledge with ongoing training (e.g., IPC-7711/7721, IPC-A-610H, IPC J-STD-001) to stay at the cutting edge of assembly standards.

Why Choose Production Logix for PCB Assembly?

-

Flexibility: From single prototypes to high-volume runs.

-

Quality: Highest industry certifications and a zero-defect mindset.

-

Technology: Advanced inspection and automation systems.

-

Expertise: Years of experience across defence, aerospace, and commercial markets.

-

Turnkey Service: Accounting for procurement, assembly, testing, and packaging.

-

Local Empowerment: South African-based and B-BBEE Level 1 certified.