Circuit Board Manufacturing: How Production Logix Powers Precision & Reliability in South Africa

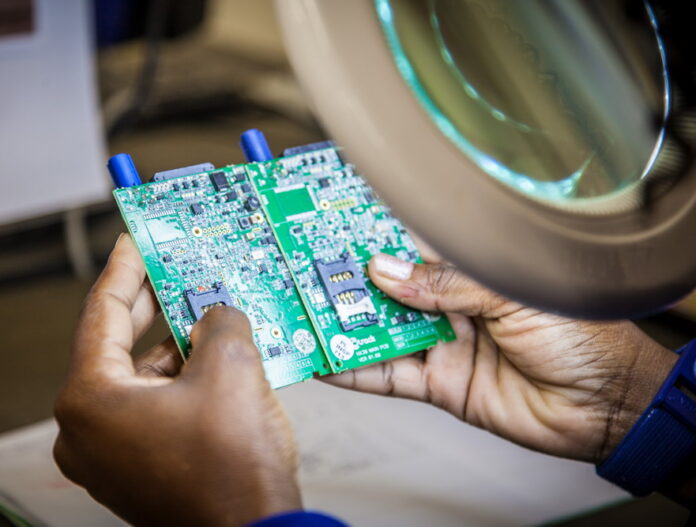

In today’s technology-driven world, circuit board manufacturing is more than simply assembling components—it is the backbone of innovation in aerospace, defence, automotive, telecoms, smart metering, and industrial electronics. Among South Africa’s leading players in this field is Production Logix (ProLogix), based in Pinetown, KwaZulu-Natal. With more than 30 years of expertise, they deliver high-quality, high-reliability electronics through contract manufacturing, with circuit board manufacturing at the heart of their service offering.

What is Circuit Board Manufacturing?

Circuit board manufacturing (or PCB / PCBA: Printed Circuit Board Assembly) is a multi-step process involving design for manufacturability, component procurement, assembly (both surface mount technology (SMT) and through-hole), soldering, inspection, testing, and final assembly. The process demands precision, traceability, quality control, and consistency. It encompasses not just the board but the full assembly: harnesses, cables, conformal coatings, ruggedisation, and quality certifications.

Production Logix’s Role & Capabilities

Production Logix operates as a full-service electronics manufacturing services (EMS) provider. Some of its capabilities and strengths in manufacturing include:

Turnkey services: From prototyping, design for manufacturability (DFM), component sourcing, SMT pick-and-place, through-hole component assembly, final/box build, cable/harness production, and testing.

Quality standards: Production Logix works under IPC Class 3 standard which is one of the highest performance standards for electronic assemblies, particularly in demanding environments. They are also certified to ISO 9001:2015 and AS9100 quality management systems, the latter particularly relevant in aerospace / defence.

High output and precision: Their facility has multiple assembly lines, able to handle high-volume component assembly, adhering to rigorous inspection and test methods such as Automated Optical Inspection (AOI), solder paste inspection, etc.

Sector diversity: Though their defence and aerospace credentials are strong, ProLogix also serves automotive, telecoms / tracking / telematics, mining, security systems, inverters and energy sectors. This spread demands adaptability in their circuit board manufacturing processes.

Why Quality & Standards Matter in Circuit Board Manufacturing

Defects, material variance, poor soldering, lack of traceability, and weak testing protocols can lead to product failures, recalls, costly repairs, reputational damage, or even critical system failures (especially in defence, aerospace, medical). Production Logix’s approach emphasises:

“Right first time” production: reducing rework, failures in field, or returns.

Full traceability & documentation: from procurement through assembly to test and final delivery. This is essential for sectors that require audit, certification, or have safety / reliability obligations.

Certifications: AS9100 ensures a quality management system aligned with aerospace & defence, and the IPC standards ensure that boards meet stringent performance and durability metrics.

Challenges & Competitive Edge

While demand for circuit board manufacturing is increasing globally, several challenges exist:

- Supply chain constraints (components shortages, long lead times)

- Cost pressures (competition, material & labour cost inflation)

- Technological complexity (miniaturisation, rapid iteration, new materials)

- Regulatory & certification demands (especially for defence, aerospace, medical sectors)

Production Logix meets these challenges through:

- Strong procurement and inventory control systems.

- Flexible, high-mix production capable of handling both prototypes/small batches and volume runs.

- Investment in inspection and test equipment to detect defects early.

Circuit board manufacturing is a complex, technically demanding, and high-stakes business. For companies like Production Logix, success lies in aligning technical capability, quality systems, process discipline, and customer focus. Their role as a contract manufacturing partner allows clients to rely on them for reliability, compliance, speed, and innovation. In South Africa’s advanced electronics landscape, Production Logix stands out as an exemplar of what high-quality circuit board manufacturing looks like done right.